So, you're looking to tile with porcelain and wondering about the glue, right? It's called thinset, and picking the right kind is a big deal. It's not just about sticking tiles down; it's about making sure they stay put for years, especially with porcelain, which can be a bit picky. We'll break down what you need to know about thinset for porcelain tile, so you don't end up with a mess.

Key Takeaways

- Porcelain tile needs a specific type of thinset mortar to ensure a strong, lasting bond.

- Modified thinsets, usually with added polymers, are generally best for porcelain due to improved flexibility and adhesion.

- Always check the tile manufacturer's recommendations for the thinset they suggest.

- Proper substrate preparation is just as important as the thinset itself for a good installation.

- Mixing thinset to the correct consistency, like thick peanut butter, is vital for its performance.

- Full coverage is key, especially for large format porcelain tiles; trowel technique matters.

- Understand the difference between thinset setting and curing times before walking on or grouting the tiles.

- Using the wrong thinset can lead to tile cracking, debonding, or other costly problems down the line.

Understanding Thinset Mortar For Porcelain Tile

The Crucial Role of Thinset in Tile Installation

Thinset mortar is the sticky stuff that holds your tiles to the floor or wall. It's not just glue; it's a specially formulated cement-based adhesive. When you're working with porcelain tile, which is known for being dense and having low water absorption, the right thinset is super important. Think of it as the foundation for your beautiful tile job. If the thinset isn't right, you can end up with tiles that pop off, crack, or just don't last. It needs to bond well, handle moisture, and stay put, especially with heavier, larger porcelain tiles that are popular these days.

Why Porcelain Tile Demands Specific Thinset Considerations

Porcelain tile is different from other types of tile. It's fired at higher temperatures, making it super dense and less porous. This means it doesn't soak up water or adhesive like ceramic tile does. Because of this, standard thinsets might not stick properly. You need a thinset that can create a strong bond with this less-absorbent surface. Getting this bond right is key to preventing loose tiles down the road. Also, porcelain can be heavy, especially large format tiles, so the thinset needs to have good strength to hold them up without sagging.

Key Components of High-Performance Thinset

A good thinset for porcelain tile usually has a few main ingredients. The base is Portland cement, which gives it its strength. Sand is often added for body and to help with shrinkage. Then, there are additives. These can include polymers, which are like super-glue boosters for adhesion and flexibility, and other chemicals that control how fast it sets, how much water it holds, and how easy it is to spread. For porcelain, you'll often want a thinset with good polymer modification to get that strong, lasting grip.

The Science Behind Thinset Adhesion

Thinset works through a chemical process called hydration. When you mix the powder with water, the Portland cement reacts with the water, forming crystals that interlock and harden. This creates a strong, rigid bond. For porcelain, the challenge is that the tile itself doesn't offer much for the thinset to grip onto chemically. That's where the physical bond and polymer additives come in. The polymers help the thinset spread thinly and evenly, filling in microscopic imperfections on both the tile and the substrate, creating a larger surface area for the adhesive to grab onto. A good trowel technique also helps ensure the thinset makes full contact.

Common Thinset Misconceptions Debunked

One big myth is that any thinset will work for any tile. Nope. Using the wrong type can lead to failure. Another idea is that more water makes thinset stronger – it's the opposite; too much water weakens it. Some people think you can just slap it on and it'll be fine, but proper mixing and application are vital. Also, not all thinsets are created equal; some are designed for specific jobs, like large format tiles or areas with lots of moisture.

Benefits of Using the Correct Thinset for Porcelain

When you pick the right thinset for your porcelain tile project, you get a few big wins. First, you get a super strong, reliable bond that lasts. This means fewer callbacks and a job you can be proud of. It also helps prevent cracking, especially if you use a thinset with good flexibility. For porcelain, this means your tiles are less likely to chip or break under stress. Plus, using the right product makes the installation process smoother, saving you time and frustration. A well-bonded tile job looks better and lasts much longer.

Impact of Improper Thinset on Tile Longevity

Using the wrong thinset can be a disaster for your tile installation. If the bond isn't strong enough, tiles can loosen, crack, or even fall off. This is especially true for heavy porcelain tiles. Moisture can seep under loose tiles, leading to mold or damage to the substrate. In areas with temperature changes, like outdoors or over radiant heat, an improper thinset might not have the flexibility needed, causing tiles to crack. Ultimately, it shortens the lifespan of your entire tile installation, leading to costly repairs and replacements.

Types of Thinset Mortar Available

When you're getting ready to tile, especially with porcelain, you'll run into different kinds of thinset mortar. It's not just one-size-fits-all, and picking the right one makes a big difference in how your tile job holds up. Think of thinset as the glue that holds everything together; you want it to be strong and suitable for the job. While there are other options like mastic, thin-set mortar is generally the go-to for most tile installations, particularly for porcelain tile installation involves three primary mortar types: thin-set, mastic, and epoxy. Thin-set mortar is the most frequently used option for laying tiles..

Portland Cement-Based Thinsets Explained

At its core, thinset is a mix of portland cement, fine sand, and additives that help it hold water. This is your basic, no-frills option. It's a reliable choice for many situations, but it has its limits. It's generally best suited for interior jobs where moisture and movement aren't major concerns. It's a solid foundation, but sometimes you need a bit more.

Modified Thinsets: The Addition of Polymers

This is where things get interesting. Modified thinsets have polymers mixed in, and these polymers do some pretty neat things. They boost the adhesive strength, making the bond tougher. They also add flexibility, which is super important for tiles that might experience some movement or temperature changes. This type is often recommended for larger tiles or areas that might get wet.

Unmodified Thinsets: Simplicity and Specific Uses

Unmodified thinset is basically the portland cement mix without those added polymers. It's simpler and often less expensive. It works well for standard interior applications, like tiling a basic bathroom floor or a kitchen backsplash, as long as the substrate is stable and dry. It's a good choice when you don't need the extra features of a modified version Unmodified thinset is a mixture of portland cement, sand, and powdered water retention additives. This type of thinset is typically used for interior applications and is suitable for most tile installations..

ANSI Standards for Thinset Classifications

To help you sort through the options, there are industry standards, mainly from ANSI (American National Standards Institute). You'll see numbers like A118.4 or A118.15. These classifications tell you about the thinset's performance characteristics, like its bond strength and flexibility. Knowing these standards helps you pick a product that meets the demands of your specific project.

When to Choose a Modified Versus Unmodified Formula

So, when do you pick which? For most residential projects, especially those involving porcelain tile, a modified thinset is often the safer bet. It handles variations in temperature and moisture better and provides a stronger bond, which is key for porcelain's density. Unmodified might be fine for very simple, interior, dry applications, but modified offers more peace of mind.

Specialty Thinsets for Unique Applications

Beyond the basic modified and unmodified types, there are specialty thinsets. These are designed for very specific situations. Think about thinsets made for rapid setting, for use over radiant heated floors, or those with extra crack-isolation properties. If your project has unique requirements, there's likely a specialty thinset made for it.

Understanding Thinset Additives and Their Functions

Those "additives" we mentioned? They're the secret sauce. Water retention agents keep the thinset workable for longer. Polymers, as we discussed, add strength and flexibility. Other additives might improve slip resistance (so your tiles don't slide around before they set) or even provide antimicrobial properties. Each additive plays a role in the final performance of the mortar.

Selecting the Ideal Thinset for Porcelain Tile

Choosing the right thinset mortar is a big deal when you're laying porcelain tile. It's not just about sticking the tile down; it's about making sure it stays put, looks good, and lasts for years. Think of it like picking the right glue for a really important project – you wouldn't use just any old craft glue for a heavy-duty repair, right? Porcelain is a bit different from other tiles, so it needs a thinset that can handle its density and low water absorption. Getting this wrong can lead to tiles that crack, loosen, or even sound hollow underfoot. We want to avoid that headache.

Matching Thinset to Porcelain Tile Properties

Porcelain tiles are dense and don't soak up much water. This means the thinset needs to be able to grab onto the tile surface really well. Some thinsets are better at this than others. You'll want to look for thinsets that are specifically recommended for porcelain, especially if you're using large format tiles. These often have additives that help with adhesion and flexibility.

Considering Tile Size and Weight

Larger and heavier porcelain tiles need a thinset with serious staying power. A standard thinset might not be strong enough to hold them securely, especially on walls. For these, you'll want a thinset with high bond strength. Some thinsets are formulated to prevent tile slippage, which is a lifesaver when you're working with big, heavy pieces.

The Importance of Water Absorption Rates

Porcelain tiles have very low water absorption, often less than 0.5%. This is great for durability but means the thinset needs to cure properly to bond. If the thinset dries out too quickly before it can fully bond, you'll have problems. Some thinsets are designed to stay workable longer, giving you more time to get a good bond, especially in warmer conditions.

Evaluating Substrate Compatibility

What are you tiling over? Concrete, cement board, plywood? Each surface has different needs. Some thinsets work better on certain substrates than others. For example, if you're tiling over concrete that might have some movement, you'll need a thinset with good flexibility. Always check the thinset manufacturer's recommendations for compatible substrates.

Environmental Factors Affecting Thinset Choice

Where are you tiling? Indoors, outdoors, a bathroom, a kitchen? High moisture areas or places with temperature swings might require a thinset with better water resistance or flexibility. For outdoor projects, you'll need something that can handle freezing and thawing. It's not a one-size-fits-all situation.

Project Scope: Residential vs. Commercial Needs

For a home bathroom, you might get away with a good quality modified thinset. But for a busy commercial space, like a mall or airport, you'll need a thinset that's built for heavy traffic and constant wear. These commercial-grade thinsets usually have superior strength and durability.

Consulting Tile Manufacturer Recommendations

This is probably the most important step. The company that made your porcelain tile usually has specific recommendations for the type of thinset to use. They know their product best and can tell you exactly what will give you the best results and warranty. Always check the tile manufacturer's installation guide before you buy your thinset.

Here's a quick rundown of what to look for:

- High Bond Strength: For heavy or large format tiles.

- Flexibility: To handle substrate movement and temperature changes.

- Water Resistance: For wet areas like bathrooms and kitchens.

- Substrate Specific Formulations: To ensure compatibility with your subfloor.

- Manufacturer Approval: The golden ticket for a successful installation.

Key Performance Characteristics of Thinset

When you're laying down porcelain tile, the stuff you use to stick it to the floor or wall – the thinset – really matters. It’s not just some sticky paste; it’s got to do a lot of work. Think about it: it holds everything in place, deals with temperature changes, and has to last for years. Getting the right kind means your tile job looks good and stays put.

Adhesive Strength and Bond Integrity

The main job of thinset is to create a strong bond between the tile and the substrate. You want a thinset that grips well and doesn't let go. For porcelain, which can be dense and heavy, this is super important. A good bond means no tiles popping off later. We're talking about a connection that can handle foot traffic, maybe even furniture being moved around. It’s the foundation of a lasting tile installation.

Flexibility and Crack Isolation Properties

Floors and walls aren't always perfectly still. They can shift a little due to temperature changes or building movement. If the thinset is too rigid, it can crack, and that crack can travel right up through your tile grout lines. Some thinsets have added flexibility, which helps absorb these small movements. This is especially useful if you're tiling over a substrate that might move a bit, like certain types of subflooring. It's like giving your tile job a little wiggle room.

Water Resistance and Moisture Management

This is a big one, especially for bathrooms, kitchens, or outdoor areas. Thinset needs to be able to handle moisture without breaking down. Some thinsets are better at resisting water than others. If water gets behind the tile and the thinset can't handle it, you can end up with mold, mildew, or a weakened bond. Choosing a thinset with good water resistance helps keep your tile installation dry and healthy.

Heat Resistance for Specific Installations

If you're tiling an area that gets hot, like around a fireplace or on a floor with radiant heating, you need a thinset that can take the heat. Standard thinsets might not hold up well under high temperatures. They can become brittle or lose their adhesive properties. Look for thinsets specifically designed for high-heat applications to avoid problems down the road. This is key for areas that experience significant temperature fluctuations.

Open Time and Working Properties

Open time refers to how long you have to work with the thinset after you spread it before it starts to skin over. Different thinsets have different open times. A longer open time can be helpful, especially for larger jobs or if you're working in a warm, dry environment where thinset dries out quickly. It gives you more time to place tiles correctly without the thinset losing its tackiness. Good working properties also mean it spreads easily and consistently.

Setting Time and Curing Durations

Setting time is when the thinset starts to harden enough to hold the tile in place. Curing time is when it reaches its full strength. These times can vary a lot between products. Some thinsets are "rapid setting," meaning you can grout and walk on the tile much sooner. Others take longer. It's important to know these times so you don't rush the process and damage your new tile floor. Always check the manufacturer's instructions for specific timelines.

Shrinkage and Stability During Curing

As thinset dries, it can shrink a little. If a thinset shrinks too much, it can pull away from the tile or substrate, creating gaps or weakening the bond. High-quality thinsets are formulated to minimize shrinkage, staying stable as they cure. This stability is vital for a strong, long-lasting installation, especially with larger format tiles that have more surface area to bond.

Understanding these performance characteristics helps you pick the right thinset for your specific project, preventing common tile installation headaches and ensuring a beautiful, durable finish. It's about matching the material to the job's demands.

When selecting thinset for your porcelain tile projects, especially for areas like concrete floors, it's wise to consider products that meet ANSI A118.4 or A118.15 standards. These certifications indicate a certain level of quality and performance that is beneficial for robust installations.

The Role of Polymers in Thinset Mortar

You know, when you're laying down porcelain tile, especially those big, beautiful slabs, you want to make sure they stick. Really stick. That's where polymers come into play in thinset mortar. It’s not just about cement and sand anymore; adding polymers changes the game.

Understanding Polymer-Modified Thinsets

So, what exactly are we talking about when we say "polymer-modified"? Basically, it means that alongside the usual Portland cement, sand, and other stuff, there are synthetic polymers mixed in. These aren't your typical household plastics; they're special additives designed to improve the mortar's performance. Think of it like adding a secret ingredient that makes everything work better. These polymers are usually added as a powder that dissolves when water is mixed in, or sometimes as a liquid latex.

How Polymers Enhance Adhesion

One of the biggest benefits of polymers is how they boost the adhesion of the thinset. They help the mortar bond more strongly to both the tile and the substrate. This is super important for porcelain, which can be a bit tricky to get to stick well. The polymers create a more flexible and tenacious bond, meaning less chance of tiles coming loose down the road. This improved bond is critical for preventing tile failure.

Improving Flexibility and Reducing Brittleness

Cement-based thinsets, on their own, can be a bit brittle. They don't handle movement or stress very well. Polymers add a much-needed dose of flexibility. This means the thinset can flex a little bit with minor shifts in the substrate or temperature changes without cracking. This flexibility is a lifesaver, especially for larger tiles or in areas where there might be some movement. It helps prevent those annoying cracks from forming in the grout lines or even under the tile itself.

Increased Water and Chemical Resistance

Polymers also make the thinset more resistant to water and certain chemicals. This is a big deal, particularly in areas like bathrooms, kitchens, or even outdoor installations where the tile will be exposed to moisture or cleaning agents. A more water-resistant thinset means less chance of moisture getting through to the substrate, which can cause bigger problems like mold or rot. It also means the bond stays strong even when exposed to everyday spills and cleaning.

The Impact of Different Polymer Types

Not all polymers are created equal, though. You'll often see terms like "latex polymers" or "re-emulsifiable polymer powders." Latex polymers, often added as a liquid, tend to offer excellent flexibility and adhesion. Re-emulsifiable polymer powders, which are more common in modern thinsets, are very versatile and can provide a great balance of properties. The specific type of polymer used can influence how the thinset performs in terms of flexibility, bond strength, and water resistance. It's worth checking the product data sheet if you need specifics.

When Polymer Modification is Essential

So, when do you absolutely need a polymer-modified thinset? Pretty much anytime you're working with porcelain tile, especially large format tiles. They're also a must for certain substrates, like painted surfaces or areas with potential movement. If you're tiling a shower, a kitchen backsplash, or an exterior patio, you'll want that extra protection and strength that polymers provide. It's really the standard for most modern tile installations.

Benefits for Large Format Porcelain Tiles

Large format porcelain tiles are beautiful, but they present unique challenges. They're heavy, and they have less grout line coverage to help distribute stress. This is where polymer-modified thinsets really shine. The superior adhesion and flexibility they offer are absolutely vital for ensuring these large tiles are securely bonded and can withstand the stresses of their size and weight. Without them, you risk tiles cracking or debonding over time. It's an investment in the longevity of your beautiful tile job.

Substrate Preparation for Optimal Thinset Adhesion

Before you even think about mixing thinset, let's talk about what it's sticking to. The surface, or substrate, is super important. If it's not prepped right, your beautiful porcelain tiles could end up loose, cracked, or worse. It’s like trying to build a house on sand – it’s just not going to last.

Ensuring a Clean and Sound Substrate

First things first: get rid of anything that doesn't belong. We're talking dust, dirt, grease, old adhesive, paint splatters – you name it. Anything loose or flaky needs to go. Think of it like giving your wall or floor a good scrub before applying a face mask. A clean surface lets the thinset grab on properly. A sound substrate means it's solid, not wobbly or soft. If you tap on it and it sounds hollow or feels weak, you've got bigger issues to deal with before tiling.

The Necessity of a Dry Installation Surface

Water is the enemy of good adhesion when it comes to thinset. Your substrate needs to be dry. Not just mostly dry, but completely dry. Any residual moisture can interfere with the chemical bonding process of the thinset as it cures. This is especially true for materials like drywall or wood, which can warp or rot if they stay wet. For areas like bathrooms or kitchens, make sure any waterproofing membranes are fully cured and dry before you start.

Addressing Substrate Levelness and Flatness

Tiles look best and perform better when they're laid on a flat surface. If your substrate is lumpy or uneven, your tiles will be too. This can lead to lippage (where one tile edge is higher than the next), which is not only a tripping hazard but also looks bad. It also means you won't get full contact between the tile and the thinset, creating weak spots. You might need to use a self-leveling compound or a floor patch to smooth things out. For porcelain tiles, especially larger formats, flatness is non-negotiable.

Properly Preparing Concrete Substrates

Concrete is a common substrate, but it's not always ready for tile right out of the gate. New concrete needs to cure for at least 28 days. Old concrete might have sealers, curing compounds, or efflorescence (a white powdery residue) that need to be removed. Grinding or shot blasting can take care of these issues. Make sure the concrete is also free of cracks. Small hairline cracks might be okay if you're using a crack isolation membrane, but larger ones need to be repaired first.

Preparing Cement Board and Backer Boards

Cement board and other backer boards are designed to be stable tile substrates, especially in wet areas. However, they still need proper preparation. Ensure all seams are taped and filled with the manufacturer's recommended thinset or setting material. Screw heads should be flush or slightly recessed, not sticking up. Some manufacturers recommend a skim coat of thinset over the entire board for added security, especially before installing tile.

Dealing with Existing Tile or Flooring

Sometimes, you might want to tile over existing tile. This is possible, but only if the old tile is well-adhered, level, and clean. You'll likely need to de-gloss the surface by sanding or using a special primer to give the new thinset something to grip. If the existing tile is cracked or loose, it has to come up. Trying to tile over a bad foundation is just asking for trouble.

The Role of Primers in Substrate Preparation

Primers aren't always needed, but they can be a lifesaver in certain situations. They can help seal porous surfaces, improve adhesion on tricky materials, or provide a barrier against moisture. Always check the thinset manufacturer's recommendations and the substrate manufacturer's guidelines to see if a primer is necessary for your specific project. Using the right primer can make a big difference in the long run for tile adhesion.

Mixing Thinset Mortar Correctly

Getting the thinset mix just right is super important for a tile job that lasts. It’s not just about dumping powder and water together; there’s a bit of a science to it, and honestly, it’s one of those steps where doing it wrong can really mess things up later. Think of it like baking – too much flour or not enough mixing, and you end up with something you definitely don't want to eat. The same goes for tile adhesive. We want a strong, reliable bond, and that starts with the mix.

Essential Tools for Mixing Thinset

Before you even think about adding water, make sure you have the right gear. You don't need a professional setup, but a few key items make a huge difference:

- Mixing Bucket: A sturdy 5-gallon bucket is standard. Get one that’s easy to clean.

- Mixing Paddle/Drill Attachment: A heavy-duty mixing paddle that attaches to a drill is a lifesaver. Trying to mix by hand is exhausting and rarely gets the consistency right.

- Measuring Container: For accurate water measurement. Don't just eyeball it.

- Trowel or Shovel: For scooping the powder and transferring it.

Determining the Right Water Ratio

This is where many DIYers stumble. The bag of thinset will have instructions, and you really need to follow them. Manufacturers usually give a range, like '4 to 5 quarts per 50 lb bag.' Start with the lower end of the recommended water amount. You can always add a little more if needed, but you can't take it out if you add too much. Adding too much water weakens the thinset significantly.

Achieving the Perfect Peanut Butter Consistency

What are you aiming for? Think thick, creamy peanut butter. It should be smooth, with no dry lumps. When you lift the paddle, the mix should fall off in a thick ribbon, not drip like water or stay stuck in a stiff blob. It needs to be workable enough to spread easily with your trowel but stiff enough to hold its shape and not slide off the tile or substrate.

The Importance of Slaking Time

After you've mixed the thinset to the right consistency, let it sit for about 5-10 minutes. This is called 'slaking.' It allows the chemicals in the thinset to fully hydrate and react. After slaking, give it another quick mix for about 30 seconds to a minute. This step is often skipped, but it's really important for developing the best possible bond strength and workability.

Avoiding Over-Mixing or Under-Mixing

Under-mixing leaves you with dry pockets and an inconsistent bond. You'll see lumps and uneven texture. Over-mixing, especially with a powerful drill, can actually break down the polymers in modified thinsets, reducing their effectiveness. It can also introduce too much air, which isn't good for the final strength. Aim for that smooth, consistent texture without going overboard.

Mixing in Batches for Consistent Results

Thinset has an 'open time' – the period it remains usable after mixing. This varies by product, but it's usually around 30-60 minutes. Don't mix more than you can use within that time. It's better to mix smaller batches more frequently to ensure the thinset you're applying is fresh and at its peak performance. This is especially true on warm or windy days when it dries out faster.

Troubleshooting Common Mixing Issues

- Too Stiff/Dry: Add a tiny bit more water, mix thoroughly, and let it rest again. Be cautious not to add too much.

- Too Watery/Runny: Add a small amount of dry thinset powder and mix well. This is harder to fix, so start with less water.

- Lumpy: Keep mixing. If lumps persist after significant mixing, you might have an old bag or an issue with the powder itself. Try to break them up with the paddle.

Getting the mix right might take a little practice, but it's a skill that pays off big time in the long run for a beautiful, durable tile installation. We ship premium thinset nationwide for your U.S. projects, ensuring you have the right materials for a professional finish.

Application Techniques for Thinset

Getting the thinset mortar applied correctly is a big part of making sure your porcelain tiles stick well and last a long time. It’s not just about slapping it on; there’s a bit of technique involved.

Choosing the Right Trowel Size

The trowel you use is super important. It has to match your tile size and the type of thinset. A trowel with too-small notches won't spread enough adhesive, and one with too-large notches will leave too much, which can cause problems later. For most standard porcelain tiles, a 1/4-inch by 1/4-inch square-notch trowel is a good starting point. But for larger format tiles, you’ll definitely want a larger notch size, maybe 1/2-inch by 1/2-inch or even larger, to get that full coverage we’ll talk about.

Proper Troweling Technique for Full Coverage

When you trowel, you want to create ridges in the thinset. Hold the trowel at about a 45-degree angle to the substrate. Drag it across the surface, making sure the ridges are consistent and all going in the same direction. This helps push out air and makes it easier to get full contact when you set the tile. Consistent ridges are key for a strong bond.

Applying Thinset to the Substrate vs. Tile

Generally, you apply the thinset to the substrate – that’s the floor or wall you’re tiling onto. Spread a workable amount, maybe enough to cover a few tiles at a time, so it doesn’t dry out before you get the tiles in. For very large format tiles or tiles with a very flat back, you might also need to apply a thin layer of thinset to the back of the tile itself. This is called back-buttering, and it’s a good way to make sure you get 100% coverage.

Ensuring Complete Coverage for Large Format Tiles

This is where things get serious for big tiles. You absolutely need full coverage. If there are voids under a large tile, it’s much more likely to crack or break under weight. Using the right trowel and back-buttering are your best friends here. You want to see thinset squeezed out around the edges when you press the tile down. This tells you you’ve got a good, solid bond across the entire surface. Check out our natural stone products for inspiration on large format installations.

Back-Butter Techniques for Enhanced Adhesion

Back-buttering means spreading a thin, even layer of thinset onto the back of the tile after you’ve already troweled the substrate. Use the flat side of your trowel or a margin trowel for this. The goal isn't to create thick ridges on the tile, but just a smooth, consistent coating that mates perfectly with the ridges on the substrate. This double-application method is a lifesaver for large, heavy tiles.

Working Within the Open Time of the Thinset

Thinset has an 'open time,' which is the window during which it remains wet enough to bond to the tile. This time varies depending on the product, temperature, and humidity. You don't want to spread too much thinset at once, or it might start to skin over before you can set the tile. If it skins over, it won't bond properly. It’s better to work in smaller sections and re-trowel if needed.

Maintaining Consistent Thinset Depth

When you trowel, aim for a consistent depth of thinset. The ridges you create should be uniform across the entire area. This ensures that all tiles sit at the same level and that the overall surface is flat. Uneven depth can lead to lippage (where one tile edge is higher than another) and can make grouting difficult. The goal is a smooth, even bed for your tiles.

Understanding Thinset Curing and Setting Times

So, you've mixed up your thinset and got that tile laid down. Now what? Patience, my friend. There's a difference between when your thinset is set and when it's fully cured. It might seem like a small detail, but it's pretty important for a tile job that lasts.

The Difference Between Setting and Curing

Think of setting as the initial hardening. This is when the thinset becomes firm enough that you can walk on it carefully or even start grouting. It's like the dough for bread rising – it's changed form, but it's not ready to eat yet. Curing, on the other hand, is the full development of strength. This is when the chemical reactions within the thinset are complete, and it reaches its maximum adhesive and structural properties. This full cure is what gives your tile its long-term durability.

Factors Influencing Setting and Curing Times

Several things can speed up or slow down this process. The type of thinset you use is a big one. Some are formulated for quick setting, while others take their time. The temperature and humidity in the room play a huge role too. Warmer, drier conditions generally mean faster setting and curing. If you're working in a cool, damp basement, expect it to take longer. The thickness of the thinset layer also matters; thicker beds take longer to dry out and cure completely. And don't forget the substrate itself – a very porous surface might wick moisture away faster, potentially affecting the cure.

When is it Safe to Grout?

This is where you look at the thinset manufacturer's instructions. Generally, most standard thinsets are ready for grouting after about 24 hours. However, some rapid-setting products might allow grouting in as little as 2-4 hours. Always check the bag! Rushing this step can lead to problems down the line, like weak spots or tiles that can be easily dislodged. It's better to wait an extra day than to have to redo the job.

The Impact of Temperature and Humidity

Cold temperatures can significantly slow down the chemical reactions in thinset. If it's too cold, the thinset might not even cure properly, leading to a weak bond. High humidity means there's more moisture in the air, which can slow down the evaporation process needed for curing. For optimal results, aim for temperatures between 50°F and 80°F (10°C and 27°C) with moderate humidity. If you're working in less-than-ideal conditions, you might need to adjust your expectations for setting and curing times. Sometimes, using a fan can help improve air circulation and speed things up a bit.

Allowing Adequate Curing Before Heavy Traffic

Even after grouting, your tile installation isn't ready for the full weight of daily life. Most manufacturers recommend waiting at least 72 hours before allowing heavy foot traffic. For areas that will see a lot of use, like entryways or kitchens, it's wise to wait even longer, perhaps up to 7 days. This allows the thinset to reach its full strength, preventing tiles from cracking or shifting under pressure. Think of it as letting a new paint job fully harden before you start moving furniture back in.

Ensuring Full Strength Development

Full strength development is the ultimate goal. This is when the thinset is at its toughest, providing a bond that can withstand daily wear and tear, temperature fluctuations, and moisture. Skipping the full cure time means you're compromising the integrity of your entire tile installation. This can lead to tiles loosening, grout cracking, and ultimately, a costly repair job. Always follow the manufacturer's guidelines for the specific thinset product you're using. For example, when you mix the adhesive according to the manufacturer's instructions, you should allow the mixture to stand for five minutes, then remix it briefly. This ensures the correct consistency for proper application.

Recognizing Signs of Improper Curing

How do you know if something went wrong? Look for signs like tiles that feel loose or hollow when tapped, grout lines that are crumbling, or even visible cracks in the tile or grout. If you notice any of these issues, it's a strong indicator that the thinset didn't cure properly. This could be due to incorrect mixing, improper environmental conditions, or using the wrong type of thinset for the job. Addressing these problems early is key to preventing further damage. Sometimes, standard thinset typically dries in 24 hours under optimal conditions, but if it's not showing signs of full strength, further investigation is needed.

Troubleshooting Common Thinset Issues

Even with the best preparation, sometimes things don't go exactly as planned with thinset mortar. Don't worry, most common problems have straightforward solutions. Let's look at what might pop up and how to fix it.

Addressing Poor Adhesion and Debonding

This is a big one – tiles that lift off easily or sound hollow when tapped often mean the thinset didn't bond properly. Usually, this comes down to a few things: the substrate wasn't clean, it was too wet, or the thinset wasn't spread evenly, leading to air pockets. The fix often involves removing the affected tiles, cleaning both the tile and the substrate thoroughly, and reapplying the thinset with proper technique. Make sure you're using the right trowel size for the tile and that you're getting full coverage. For larger tiles, back-buttering (applying thinset to the tile itself) is often a good idea.

Dealing with Crumbling or Powdery Thinset

If your thinset is crumbling or feels like powder after it's supposed to have set, it's a sign it didn't cure correctly. This can happen if too much water was added, if it was mixed improperly, or if it dried out too quickly before it could fully hydrate. Sometimes, using an old bag of thinset that has absorbed moisture from the air can also cause this. The solution is to remove the affected material and start over, paying close attention to the mixing instructions and water ratio. Always use fresh thinset from a sealed bag.

Identifying and Rectifying Hollow Spots

Hollow spots under tiles are usually caused by insufficient thinset coverage or improper troweling. When you tap a tile and hear a dull thud instead of a solid sound, that's a hollow spot. This means there's no thinset bonding there, which can lead to cracking or tile failure down the line. If you catch this before the thinset is fully cured, you might be able to gently press the tile down to spread the mortar. If it's already cured, the tile will likely need to be removed, the thinset scraped off, and the tile re-set with proper coverage.

Managing Efflorescence on Tile Surfaces

Efflorescence looks like a white, powdery residue that can appear on tile or grout lines. It's caused by salts and minerals in the cementitious materials (like thinset and grout) reacting with water. As the water evaporates, it leaves these salts behind. While it can be unsightly, it's usually not a sign of structural failure. Often, it can be wiped away with a damp cloth once the area is dry. If it's persistent, you might need to address the source of excess moisture or use a specific efflorescence cleaner. Ensure your installation is properly sealed, especially in wet areas.

Correcting Grout Line Inconsistencies

Uneven grout lines can stem from inconsistent thinset depth or tiles shifting during installation. If the issue is minor and caught early, you might be able to adjust the tiles before the thinset sets. For cured installations, the only real fix is to remove the grout, and in some cases, the tile, to re-level the installation. Using tile spacers consistently during installation is key to preventing this.

What to Do About Thinset Stains

Sometimes, excess thinset can ooze up between tiles or get smeared on the tile face. If it's still wet, wipe it away immediately with a damp sponge. If it has dried, you might need a grout sponge or a specialized cleaner. Be careful not to damage the tile finish, especially with polished porcelain. Always have a damp sponge or cloth handy during installation.

Preventing Future Thinset-Related Problems

Most thinset issues boil down to preparation and application. Here’s a quick checklist to avoid them:

- Proper Substrate Prep: Make sure it's clean, dry, and sound.

- Correct Mixing: Follow the manufacturer's instructions precisely for water ratio and consistency.

- Right Trowel Size: Use the recommended trowel for your tile size to get full coverage.

- Consistent Application: Spread the thinset evenly and avoid leaving large air pockets.

- Workable Open Time: Don't let the thinset skin over before setting the tile.

By paying attention to these details, you can significantly reduce the chances of encountering problems down the road. We ship our premium thinset nationwide, so you can get the quality materials you need for a successful U.S. project, no matter where you are.

Special Considerations for Large Format Porcelain

Large format porcelain tiles, those giants of the tiling world, bring a modern, expansive look to any space. But let's be real, they're not like laying down small, manageable squares. These big boys need a bit more attention to detail, especially when it comes to the thinset holding them in place. Using the wrong approach can lead to headaches down the road, like cracked tiles or uneven surfaces. We ship nationwide, so whether you're tackling a project in a bustling city or a quiet suburb, these tips apply.

Why Large Format Tiles Need Enhanced Support

Think of it this way: a larger tile has more surface area that needs to be fully supported by the adhesive. If there are voids underneath, the tile is more prone to flexing, which can cause it to crack under pressure. This is especially true for tiles that might be subjected to heavy foot traffic or furniture. Proper support from the thinset is non-negotiable for long-term durability.

The Criticality of Full Thinset Coverage

This is probably the most important point. With large format tiles, you absolutely must achieve 100% thinset coverage on both the back of the tile and the substrate. This isn't a 'close enough' situation. Gaps in coverage create weak spots. This means you'll likely need to use a larger trowel size and employ a technique called 'back-buttering' to ensure no part of the tile is left unsupported.

Recommended Trowel Sizes for Large Tiles

Choosing the right trowel is key to getting that full coverage. While standard tiles might get away with a 1/4-inch trowel, large format tiles often require a larger notch size, typically ranging from 1/2 inch to 3/4 inch, or even a larger square-notch trowel. The exact size depends on the tile's specific dimensions and the manufacturer's recommendations. Always check the thinset and tile manufacturer's guidelines.

The Importance of Back-Butter Techniques

Back-buttering is the practice of applying a thin, even layer of thinset directly onto the back of the tile in addition to applying it to the substrate. For large format tiles, this is often a requirement. It helps fill any slight imperfections on the tile's surface and ensures that when you press the tile into the substrate, the thinset spreads out to create that complete bond. It's a bit more work, but it's vital for these larger pieces.

Using Thinsets with Superior Adhesion Properties

Not all thinsets are created equal, and for large format porcelain, you'll want a high-performance option. Look for thinsets specifically designed for large format tiles or those with superior adhesion strength. Modified thinsets, which contain polymers, are generally recommended because they offer better flexibility and bond strength compared to unmodified versions. This extra grip is what these big tiles need.

Ensuring Substrate Flatness for Large Tiles

Large format tiles are unforgiving when it comes to substrate flatness. Any dips or humps in the subfloor will be magnified by the large tile. If your substrate isn't perfectly flat, the thinset won't be able to make full contact with the entire back of the tile, leading to those dreaded voids. You might need to use a self-leveling underlayment or a repair mortar to get the surface just right before you start tiling.

Advanced Thinset Solutions for Large Format Installations

Sometimes, standard practices aren't enough. For very large or heavy tiles, or installations in demanding environments (like outdoors or areas with significant temperature fluctuations), you might need to consider advanced thinset solutions. These could include specialized high-bond thinsets, crack-isolation membranes that work in conjunction with the thinset, or even epoxy-based adhesives for extreme durability. Always consult the tile manufacturer's installation guide for their specific recommendations for your project.

Environmental Factors Affecting Thinset Performance

When you're laying down porcelain tile, it's not just about the tile and the thinset itself. The environment where you're working plays a pretty big role too. You can't just slap thinset down anywhere and expect it to hold up perfectly, especially if you're dealing with tricky conditions. Thinking about the weather and the general surroundings is key to a job that lasts.

The Impact of High Humidity on Thinset

High humidity can really mess with how thinset dries. When the air is thick with moisture, it slows down the evaporation process. This means your thinset might take a lot longer to set than the bag says. If you try to rush it or walk on it too soon, you could end up with weak spots or tiles that don't bond properly. It's like trying to dry laundry on a super damp day – it just takes forever. This can lead to issues down the road, like tiles that feel loose or even crack. Always check the manufacturer's guidelines for specific humidity recommendations.

Temperature Extremes and Thinset Application

Temperature is another big one. Applying thinset when it's too hot or too cold can cause problems. On a really hot day, the thinset can dry out too quickly before the tile is even set, leading to a poor bond. On the flip side, if it's freezing, the water in the thinset can freeze, damaging the cementitious components and preventing it from ever reaching full strength. Most thinsets have a recommended temperature range, usually between 50°F and 90°F (10°C and 32°C). Sticking to this range is pretty important for a solid installation.

Outdoor Installations and Weather Resistance

Putting tile outside means it's exposed to all sorts of weather. Your thinset needs to be able to handle rain, sun, and temperature swings. Not all thinsets are made for this. You'll need one that's specifically designed for exterior use, offering good water resistance and durability against the elements. Using the wrong type can lead to premature failure, with tiles popping off or grout lines deteriorating. It’s worth looking into exterior tile installation materials that are built tough.

Freeze-Thaw Cycles and Thinset Durability

If you live in a climate that gets freezing temperatures, freeze-thaw cycles are a major concern for outdoor tile. When water gets into the thinset and then freezes, it expands. This expansion can put a lot of stress on the bond between the tile and the substrate, potentially causing the tile to crack or debond. Thinsets designed for exterior use often have additives that give them better flexibility and resistance to these cycles, helping to prevent damage.

Moisture Vapor Transmission Rates

Sometimes, moisture can come up from the ground through the concrete slab. This is called moisture vapor transmission. If your thinset isn't equipped to handle this, the moisture can get trapped under the tile and weaken the bond over time. Some thinsets are better at allowing moisture to pass through or are more resistant to it. For areas with high moisture vapor transmission, you might need a specialized thinset or a moisture barrier system. Understanding the moisture issues in your subfloor is key.

Choosing Thinset for Wet Areas Like Bathrooms

Bathrooms and showers are obviously wet places. The thinset used here needs to be highly water-resistant. While the tile and grout are the primary barriers, the thinset is the foundation. Using a thinset that can withstand constant moisture without breaking down is critical. Many modified thinsets offer better water resistance than unmodified ones, making them a good choice for these areas. Some even have antimicrobial properties to help prevent mold and mildew.

Adapting Thinset for Climate-Specific Needs

Every region has its own climate quirks. Whether it's intense desert heat, coastal humidity, or harsh winter conditions, the environment dictates the type of thinset you should use. Always consider the specific challenges of your local climate when selecting your thinset. A thinset that works perfectly in Arizona might not hold up well in Seattle. Consulting with local tile suppliers or professionals can give you insights into what performs best in your area. For nationwide shipping on premium natural stone and tile installation supplies, explore options that cater to diverse environmental demands.

Thinset for Radiant Heated Floors

Installing tile over a radiant heated floor system requires special attention to the thinset mortar you choose. It's not just about sticking the tile down; it's about making sure the whole system works efficiently and lasts a long time. Regular thinset might crack or lose its grip when subjected to the constant heating and cooling cycles.

Specific Thinset Requirements for Heated Floors

When you're tiling over a radiant heating system, you need a thinset that can handle temperature changes. This means looking for mortars that are formulated to be flexible and resistant to thermal shock. The goal is to prevent the tile from cracking or becoming loose due to the expansion and contraction of the subfloor and heating elements.

Ensuring Thermal Shock Resistance

Thermal shock happens when a material experiences rapid temperature changes. In a heated floor, the tiles and the thinset are repeatedly heated and cooled. A thinset that can't handle this will eventually fail. Look for thinsets specifically labeled as "heat resistant" or "for use with radiant heat."

Flexibility to Accommodate Expansion and Contraction

Radiant heating systems cause materials to expand when warm and contract when cool. Your thinset needs to be flexible enough to move with these changes without breaking. This flexibility is key to preventing cracks in both the tile and the grout lines over time. Modified thinsets, which contain polymers, are generally a good choice here because they offer improved flexibility.

Thinset Formulations Designed for Heat

Some manufacturers offer thinsets specifically engineered for radiant heated floors. These often have advanced polymer additives that provide superior bond strength and flexibility. Always check the product's technical data sheet to confirm its suitability for heated subfloors.

Proper Application Techniques for Heated Substrates

Applying thinset over a heated substrate is similar to other tile jobs, but with a few extra points to consider:

- Ensure the heating system is off and the substrate is cool. Never apply thinset to a warm or hot surface.

- Use the correct trowel size to achieve full coverage. This is especially important for large format tiles.

- Apply consistent pressure when setting the tile to ensure good contact with the thinset.

- Avoid disturbing the tiles once they are set, as this can compromise the bond.

Allowing Adequate Curing Before System Activation

This is a big one. You absolutely must let the thinset cure completely before turning on the radiant heating system. Activating the heat too soon can cause the thinset to cure improperly, leading to weak spots or cracks. Most manufacturers recommend waiting at least 7 days, but always check the specific product's instructions.

Avoiding Common Mistakes with Heated Floor Thinset

- Using standard, unmodified thinset.

- Turning on the heat too soon after installation.

- Not achieving full trowel coverage, leading to voids.

- Failing to check the thinset's compatibility with radiant heat systems.

Choosing the right thinset and applying it correctly are vital steps for a successful and long-lasting radiant heated tile floor. It's an investment in comfort and durability for your U.S. project.

Thinset for Exterior Porcelain Tile Installations

When you're planning to tile an outdoor space, whether it's a patio, walkway, or even a pool deck, the thinset mortar you choose is super important. It's not quite the same as what you'd use indoors. Outdoor installations face a lot more challenges, like changing weather, temperature swings, and moisture. Picking the right stuff means your beautiful porcelain tiles will stay put and look good for a long time.

Weatherproof Thinset Mortar Essentials

For exterior projects, you need a thinset that can handle the elements. This means it needs to be resistant to water and UV rays. Standard indoor thinsets might break down over time when exposed to rain, sun, and freezing temperatures. Look for thinsets specifically labeled for exterior use. These are usually polymer-modified, which gives them extra strength and flexibility. A good exterior thinset is your first line of defense against weather-related tile failure.

UV Resistance and Durability Outdoors

The sun can be tough on building materials. Prolonged exposure to UV rays can degrade some adhesives, leading to a weaker bond. Exterior thinsets are formulated to resist this breakdown. This means the bond between your porcelain tile and the substrate stays strong, even after years of direct sunlight. It's all about making sure your tiles don't start to loosen or crack just because they're outside.

Thinset Formulations for Freeze-Thaw Stability

If you live in a climate that experiences freezing temperatures, this is a big one. When water gets into tiny cracks in the thinset or tile and then freezes, it expands. This expansion can put a lot of stress on the bond. Thinsets designed for exterior use often have additives that make them more flexible and less prone to cracking under these freeze-thaw cycles. This is especially important for areas that get wet, like around pools or in rainy regions.

Adhesion to Outdoor Substrates

Outdoor substrates can be different from indoor ones. You might be tiling over concrete slabs, prepared soil, or even specialized outdoor backer boards. The thinset needs to be able to form a strong, lasting bond with whatever surface you're working on. Look for thinsets that list compatibility with common outdoor materials. A strong initial bond is key, but it's the long-term adhesion under stress that really matters for exterior projects.

Waterproofing and Drainage Considerations

While the thinset itself isn't the primary waterproofing layer, its ability to resist water is vital. You also need to think about drainage. Water shouldn't pool on your tiled surface. Proper slope and drainage systems are necessary, but the thinset should also be able to handle occasional moisture without degrading. Some thinsets offer better water resistance than others, which is a plus for any outdoor application, especially in damp or humid climates.

Application Guidelines for Exterior Projects

Applying thinset outdoors has its own set of rules. You need to work within the product's open time, which can be affected by sun and wind. Always check the manufacturer's instructions for specific temperature ranges and humidity levels for application. It's often best to tile when the weather is mild and predictable. For large format tiles, which are common for modern outdoor spaces, using a high-quality, polymer-modified thinset like VersaBond Gray Fortified Thin-Set Mortar is highly recommended to ensure full coverage and a robust bond.

Selecting Thinset for Patios and Pool Decks

When choosing thinset for patios, you're looking for durability and resistance to foot traffic and weather. For pool decks, the stakes are even higher. The thinset must withstand constant moisture, chemicals (like chlorine), and temperature fluctuations. Look for thinsets that are specifically rated for submerged applications if you're tiling inside a pool. For decks around the pool, prioritize water resistance, freeze-thaw stability, and excellent adhesion. It’s a good idea to consult with tile and thinset manufacturers to get their specific recommendations for these demanding environments.

Understanding Thinset Standards and Certifications

When you're picking out thinset for your porcelain tile project, you'll see a lot of numbers and letters, like ANSI A118.4 or A118.15. What does all that mean? Basically, these are standards set by the American National Standards Institute ANSI standards that tell you how well a particular thinset is supposed to perform. Think of them as a quality check.

The Role of ANSI Standards in Thinset

These standards are pretty important because they give us a way to compare different thinset products. They test things like how strong the bond is, how much it can stretch without breaking, and how well it holds up against water. For porcelain tile, especially the larger formats that are popular now, you need a thinset that can handle the job. Using a thinset that meets the right ANSI standard means you're more likely to get a tile installation that lasts.

Decoding Thinset Classifications (e.g., A118.4, A118.15)

Let's break down a couple of common ones you'll see:

- ANSI A118.4: This is a pretty standard requirement for most cementitious tile grouts and mortars. It covers basic bond strength and water resistance. It's a good starting point for many indoor projects.

- ANSI A118.15: This is a higher performance standard. Thinsets meeting A118.15 offer improved bond strength, better flexibility, and often greater resistance to chemicals and moisture. This is usually the go-to for demanding applications, like large format porcelain tiles or areas with potential movement.

What Certifications Mean for Performance

When a thinset is certified to meet a certain ANSI standard, it means it's been tested by an independent lab and proven to meet those specific performance criteria. It's not just marketing hype; it's a verifiable measure of quality. This is especially important when you're working with materials like porcelain tile, which can be less forgiving than other types if not installed correctly.

Importance of Choosing Certified Thinsets

Why bother with certified thinsets? Well, it boils down to reliability. You're investing time and money into your tile project, and you want it to look good and hold up for years. Using a thinset that meets the appropriate standard gives you peace of mind. It means the manufacturer has put the product through its paces, and it's ready for the challenges of a real-world installation. For nationwide shipping on projects across the U.S., knowing your materials meet these standards is key.

How Standards Ensure Quality and Reliability

These standards act as a baseline. They prevent manufacturers from selling products that simply won't do the job. For porcelain tile, which has very low water absorption and can be prone to cracking if not properly supported, a thinset that meets a higher standard like A118.15 is often recommended. It's about making sure the bond between the tile and the substrate is strong and durable, no matter the conditions.

Navigating Technical Data Sheets

Don't be afraid to look at the technical data sheet (TDS) for a thinset. This document will list the ANSI standards the product meets, along with other important details like open time, setting time, and recommended trowel sizes. It's your best friend when trying to figure out if a specific thinset is the right fit for your porcelain tile and your project.

Selecting Thinset Based on Performance Ratings

Ultimately, understanding these standards helps you make a smarter choice. For a simple bathroom floor with smaller tiles, a standard A118.4 might be fine. But for a large living room with big, heavy porcelain tiles, you'll want to look for something that meets A118.15 or even higher-performance specifications. It's about matching the material's capabilities to the demands of the job.

Advanced Thinset Technologies

When you're tackling a tile project, especially with something as demanding as porcelain, the right thinset mortar is key. While standard options get the job done, the tile industry is always innovating. This means there are some pretty cool advanced thinset technologies out there that can make your life easier and your tile installation last longer. Let's look at a few.

Rapid Setting Thinsets for Quick Turnarounds

Sometimes, you just need to move fast. Maybe you've got a tight deadline for a commercial space or you're just eager to get your bathroom back in commission. Rapid setting thinsets are formulated to cure much faster than traditional mortars. This means you can grout and walk on the tiles in a fraction of the time. It’s a real game-changer for projects where time is of the essence. You can often grout within a few hours, and heavy foot traffic might be possible the next day. This speed doesn't usually mean a compromise on strength, either, as many are designed to meet high performance standards.

Self-Leveling Thinset Mortars

Dealing with uneven subfloors can be a major headache. Self-leveling thinset mortars are a fantastic solution for creating a perfectly flat surface before you lay your tiles. You mix it up, pour it onto the floor, and it flows out to create a smooth, level plane. This is particularly helpful for large format tiles, which can highlight even minor imperfections in the subfloor. It saves a lot of time and effort compared to manually troweling and leveling.

Thinsets with Enhanced Crack Isolation Properties

Cracks happen. Whether it's from subfloor movement, settling, or temperature changes, cracks in the substrate can transfer up through your tile installation, leading to popped tiles or grout lines. Thinsets with enhanced crack isolation properties act as a barrier. They have built-in flexibility that can absorb minor movements in the subfloor, preventing those cracks from reaching your beautiful tile. This is a big deal for longevity, especially in areas prone to movement or in larger installations.

Antimicrobial Properties in Thinset

In areas prone to moisture, like bathrooms, showers, or kitchens, mold and mildew can be a concern. Some advanced thinsets now come with antimicrobial additives. These additives help inhibit the growth of mold and mildew within the mortar itself. While it's not a substitute for proper ventilation and waterproofing, it adds an extra layer of protection against common microbial issues, keeping your installation cleaner and healthier.

Low-Dust Mixing Formulations

Anyone who has mixed thinset knows the cloud of dust that can erupt. Low-dust formulations are a godsend for indoor projects or for anyone sensitive to dust. These products are engineered to significantly reduce the amount of airborne dust during mixing. It makes the job cleaner, safer, and generally more pleasant, especially if you're working in a finished living space. You can find products like UZIN CX 20 that offer professional-grade performance with improved handling characteristics.

The Future of Thinset Innovation

The tile industry is constantly evolving, and so are the materials used to install it. We're seeing a trend towards thinner, stronger, and more versatile mortars. Expect to see even more specialized formulations addressing specific installation challenges, perhaps with even faster setting times, improved flexibility, or better adhesion to tricky surfaces. The goal is always to make the installer's job easier and the final result more durable and attractive. For demanding projects, especially those involving large format porcelain tiles, choosing a thinset with advanced properties is often the smartest move.

Choosing Cutting-Edge Thinset Solutions

When you're looking at advanced thinset technologies, it's important to match the product to your specific project needs. Read the manufacturer's technical data sheets carefully. They'll tell you what the thinset is designed for, its setting times, its flexibility, and its compatibility with different substrates and tile types. Don't be afraid to ask for advice from tile suppliers or experienced installers. Using the right advanced thinset can make a significant difference in the quality and longevity of your tile work.

Cost-Effectiveness of Premium Thinset

The True Cost of Using Inferior Thinset

It might seem like a good idea to save a few bucks upfront by grabbing the cheapest thinset you can find. But honestly, that's usually a bad move. When you use a low-quality adhesive, you're basically setting yourself up for problems down the road. Think about it: if the thinset doesn't bond properly, your tiles could end up loose, cracked, or even falling off. That means you'll have to pay for repairs, buy more tiles, and spend more time fixing it all. It's way more expensive in the long run than just using a good product from the start.

Long-Term Savings with High-Quality Adhesives

Investing in a premium thinset mortar, especially one formulated for porcelain tile, is like buying insurance for your project. These high-performance adhesives are designed to create a strong, lasting bond that can withstand the demands of daily life. They offer better flexibility, water resistance, and overall durability. This means fewer callbacks, happier clients (if you're a pro), and a tile installation that looks great for years. For homeowners, it means peace of mind and avoiding costly repairs later on. It’s about getting a solid foundation for your beautiful tile work.

Reducing Repair and Replacement Expenses

Poor adhesion is a leading cause of tile failure. When thinset doesn't stick well, tiles can become hollow underneath, leading to cracking or delamination. This is especially true for larger format porcelain tiles, which have more surface area to bond. Using a thinset with superior adhesive strength and proper application techniques significantly reduces the risk of these issues. Think about the cost of re-tiling a bathroom floor or a kitchen backsplash – it adds up fast! A quality thinset prevents these headaches and saves you money on repairs and replacements. For example, using a thinset designed for large format tiles can prevent costly failures. Learn about thinset.

The Value of a Reliable Bond

A reliable bond is the backbone of any successful tile installation. Premium thinsets are engineered with advanced polymer additives that significantly boost their bonding capabilities. This means they can adhere strongly to a variety of substrates, including concrete, cement board, and even existing tiles, provided they are properly prepared. This strength is particularly important for porcelain, which is dense and has low water absorption, making it harder for some adhesives to grip. A strong bond means your tiles are less likely to shift, crack, or become loose over time, preserving the aesthetic and structural integrity of your project.

Calculating Thinset Needs Accurately

Before you even think about buying thinset, it's smart to figure out exactly how much you'll need. Most thinset bags will have a coverage chart on them, showing how many square feet you can cover with a certain trowel size. It's always better to buy a little extra than to run out halfway through the job. Running out means an extra trip to the store, potential color variations if you get a different batch, and delays. Measure your area, check the bag for coverage estimates based on your trowel size, and add about 10-15% for waste or mistakes. This helps you budget correctly and avoid unexpected costs.

Comparing Thinset Prices and Performance

When you're shopping for thinset, you'll see a range of prices. The cheapest options are usually basic, unmodified Portland cement-based mortars. As you move up in price, you'll find modified thinsets with added polymers, and then specialty thinsets for specific applications like large format tiles or exterior use. Don't just grab the cheapest bag. Look at the performance ratings and what the manufacturer recommends for your specific tile and substrate. Sometimes, spending an extra $10-$20 per bag on a high-performance thinset can save you hundreds or even thousands in potential repair costs later. It's about finding the best value, not just the lowest price.

Investing in Durability Through Proper Thinset Choice

Ultimately, choosing the right thinset is an investment in the longevity and appearance of your tiled surfaces. A premium thinset provides the necessary strength, flexibility, and resistance to moisture and environmental factors that ensure your tile installation stands the test of time. This is especially true for high-traffic areas or spaces exposed to moisture. While the initial cost might be slightly higher, the long-term benefits of reduced maintenance, fewer repairs, and a consistently beautiful finish far outweigh the upfront expense. For professional installers, this translates to satisfied clients and a stronger reputation, while homeowners benefit from a durable, attractive space. The cost to install tile can be significant, so protecting that investment with the right materials is key.

Thinset for Specific Porcelain Tile Finishes

Choosing the right thinset mortar is super important, especially when you're working with different types of porcelain tile finishes. It's not just about sticking the tile down; it's about making sure it stays put and looks good for years to come. Different finishes have different needs, and using the wrong thinset can cause all sorts of headaches down the road.

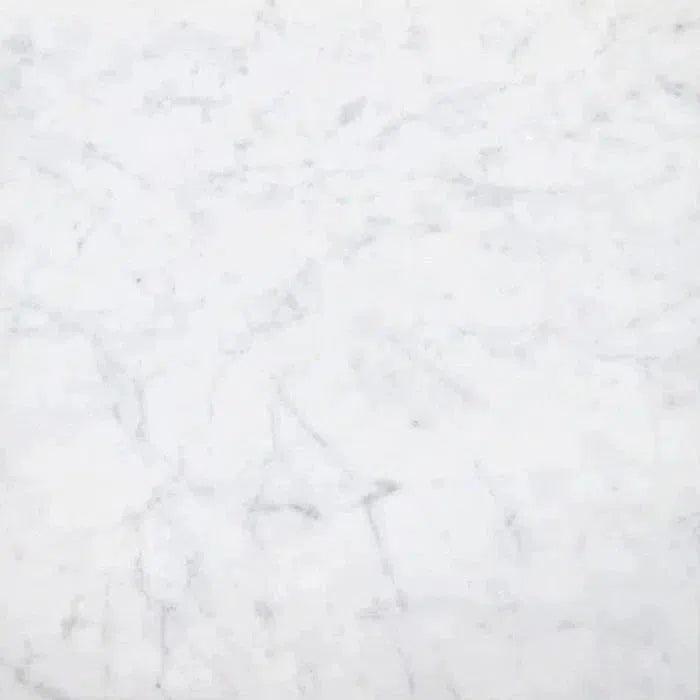

Polished Porcelain and Thinset Compatibility

Polished porcelain tiles have a super smooth, reflective surface. Because they're so smooth, they can sometimes be a bit trickier to get a good bond with. You need a thinset that offers excellent adhesion. A high-quality, polymer-modified thinset is usually your best bet here. It helps create a strong, lasting bond without damaging that beautiful polished finish. Make sure the thinset is designed for smooth surfaces and offers superior bond strength. We ship nationwide, so your project, wherever it is in the U.S., can benefit from the right materials.

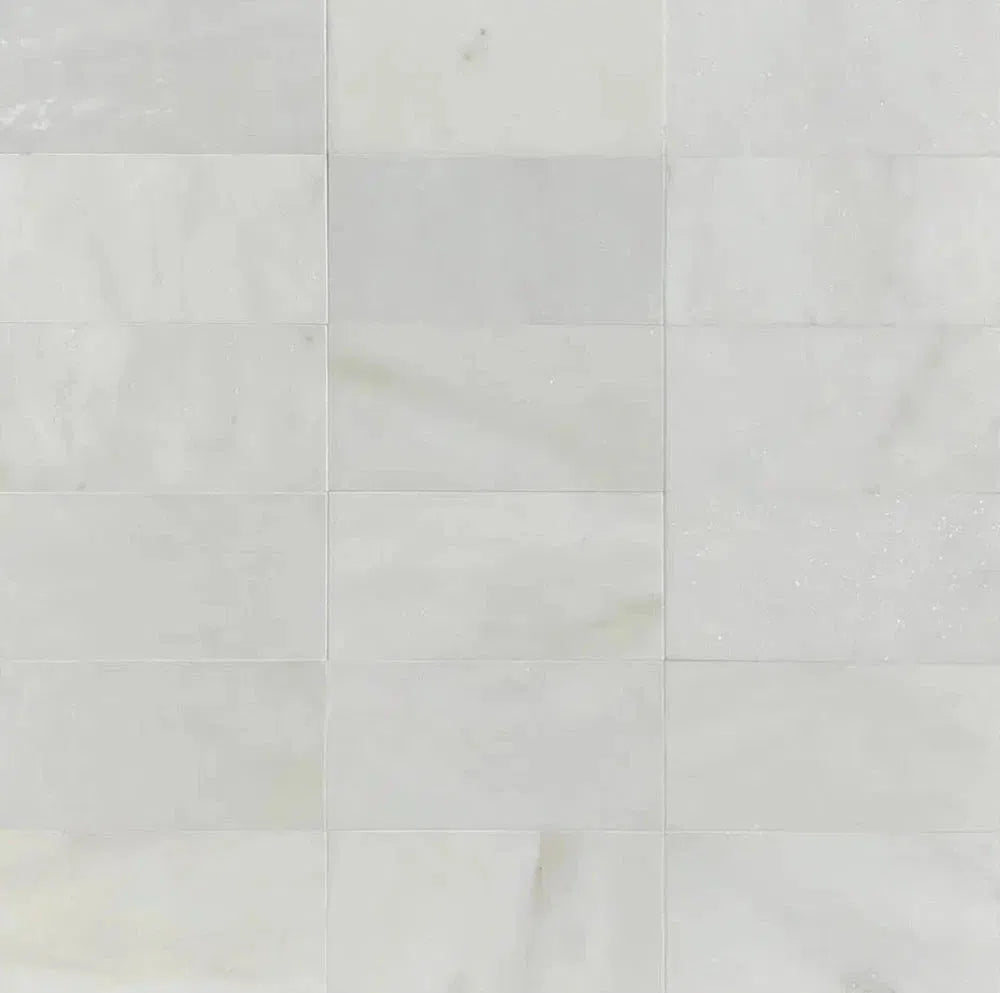

Textured Porcelain and Adhesion Challenges

Tiles with textured surfaces, like those mimicking natural stone or wood, can present their own set of adhesion challenges. The texture might create tiny voids or uneven contact points. You'll want a thinset that can fill these small gaps and still provide full coverage. Look for thinsets that are known for their flexibility and ability to accommodate slight surface irregularities. This helps prevent the textured areas from becoming weak points.

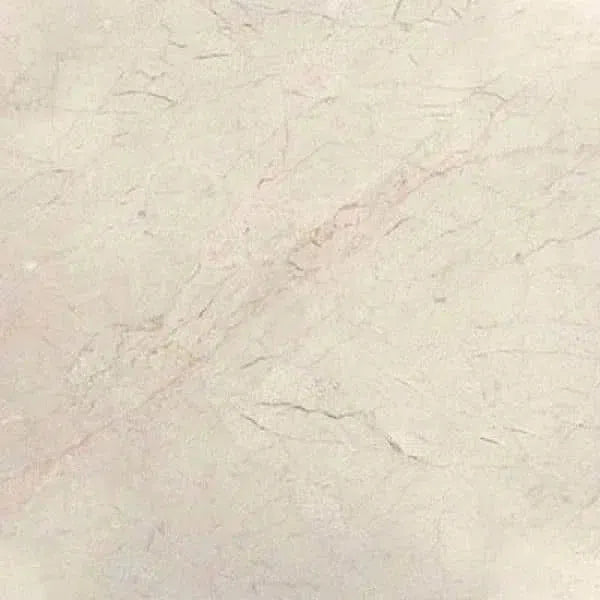

Matte Finish Porcelain Tile Considerations

Matte finish porcelain tiles are generally less prone to adhesion issues than polished ones because their surface isn't as slick. However, they still require a reliable bond. A good quality, unmodified or modified thinset, depending on your substrate and project needs, will work well. The key is to ensure consistent application and full coverage, just like with any other tile.

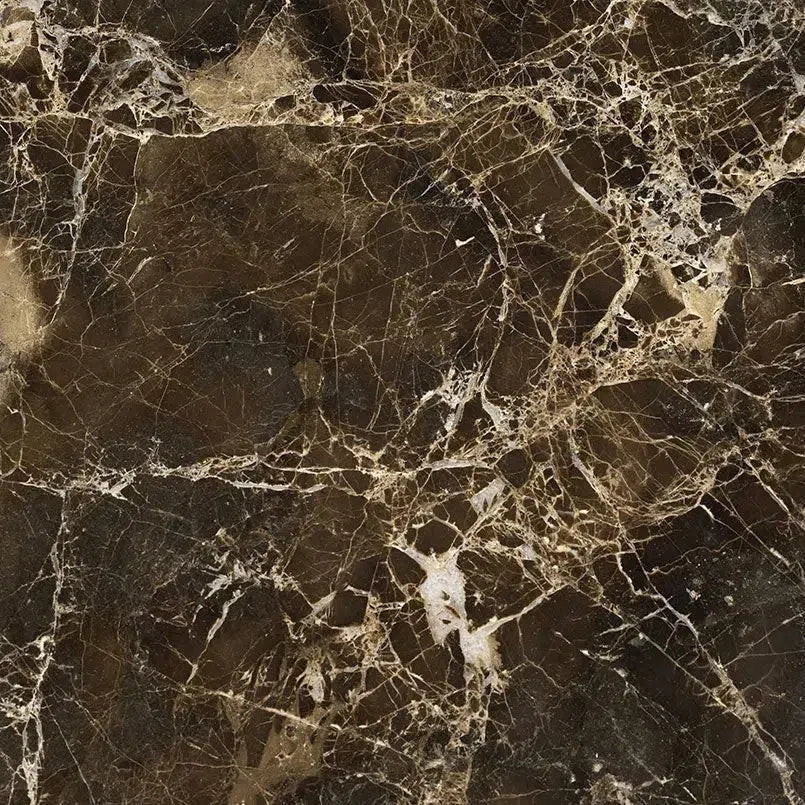

The Impact of Tile Glaze on Thinset Choice

The glaze on a porcelain tile can affect how well the thinset adheres. Some glazes are very dense and non-porous, which can make bonding more difficult. In these cases, a thinset with enhanced adhesive properties, often found in polymer-modified formulas, is recommended. Always check the tile manufacturer's guidelines; they might specify certain types of thinset that work best with their specific glazes.

Thinset for Unglazed Porcelain

Unglazed porcelain tiles are essentially the same material all the way through. They tend to be more porous than glazed tiles, which can actually help with adhesion. However, they can be more susceptible to staining from the thinset if not applied correctly. Using a clean, consistent application method and a thinset that cures to a neutral color can help prevent this.

Ensuring Uniformity with Different Finishes

When you're working with a project that might involve multiple finishes of the same porcelain tile, or even different types of tiles, it's important to use a thinset that can handle them all. A versatile, high-performance thinset will provide consistent results across various surfaces. This avoids issues where one tile might adhere better than another simply because of its finish.

Matching Thinset to Surface Aesthetics

While the primary goal is a strong bond, the aesthetic of the tile finish should also be considered. You don't want a thinset that will somehow discolor or negatively impact the look of your tile. For highly reflective finishes like polished porcelain, using a white thinset can sometimes be beneficial to avoid any graying effect showing through the tile. Always test a small area if you're unsure.

DIY vs. Professional Thinset Selection

When it comes to tiling projects, especially with something as specific as porcelain tile, the choice of thinset mortar is a big deal. You might be thinking, 'How hard can it be to pick out some adhesive?' Well, it's a bit more involved than grabbing the first tub you see. This is where the DIYer meets the pro, and understanding the differences can save you a lot of headaches down the road.

Empowering the Homeowner with Knowledge

As a homeowner tackling a renovation, you've probably spent hours researching tile styles, grout colors, and maybe even watched a few DIY tiling videos. It's great to be informed! Knowing about thinset types, like modified versus unmodified, and understanding what ANSI standards mean can make you a more confident shopper. You can walk into the tile store and ask informed questions, rather than just hoping for the best. Being knowledgeable helps you avoid common pitfalls. For instance, realizing that not all thinsets are created equal is a huge step. You'll start looking at product labels more closely and understanding what those numbers and letters actually signify for your project.

When to Rely on Professional Expertise

Let's be real, sometimes a project is just beyond a weekend warrior's skill set. Professionals have years of hands-on experience. They've seen what happens when the wrong thinset is used, or when conditions aren't quite right. They know how to read the subtle cues of a substrate, how to mix thinset to the perfect consistency every single time, and how to apply it for maximum coverage, especially with large format porcelain tiles. They also have access to a wider range of professional-grade products that might not be readily available to the average consumer. For complex jobs or when you want a guarantee of quality, professional tile installations are often the way to go.

Common DIY Thinset Mistakes to Avoid

DIYers often run into a few common issues with thinset. One of the biggest is not using the right type of thinset for the specific tile and substrate. For example, using an unmodified thinset on a substrate that requires flexibility can lead to cracking later on. Another mistake is improper mixing. Too much water weakens the bond, while too little makes it unworkable. Not troweling correctly, leading to poor coverage (especially on the back of the tile), is also a frequent problem. This can result in hollow spots and eventual tile failure.

Understanding Product Labels and Instructions

Product labels are your best friend, whether you're DIYing or hiring a pro. They tell you what the thinset is designed for, its open time, setting time, and any special requirements. Always read the manufacturer's instructions carefully. They'll specify:

- The recommended trowel size.

- The correct water-to-thinset ratio.

- The required substrate preparation.

- The appropriate applications (e.g., interior walls, exterior floors).

The Benefits of Professional Installation Experience

Professionals bring more than just tools; they bring experience. They understand how environmental factors like temperature and humidity affect thinset performance. They know how to deal with challenging substrates and can anticipate potential problems before they arise. This experience translates into a more durable, aesthetically pleasing, and long-lasting tile installation. They've likely encountered and solved almost every thinset-related issue imaginable, making them invaluable for complex or high-stakes projects.

Choosing the Right Thinset for Your Skill Level

If you're a beginner, start with simpler projects and thinsets that are more forgiving. Look for products that have a longer open time, giving you more working time. As you gain confidence and experience, you can move on to more specialized thinsets or tackle more challenging tile types. Don't be afraid to ask for advice at the tile supply store; they can often point you toward products that match your skill level and project needs.

Seeking Guidance for Complex Projects